Lightweight Dobson Telescopes And High Quality Parabolic Mirrors - Made in Germany!

For a few months only: reduced prices for the Infinity NL model series

20"f/3 and 25"f/3 Dobsonian Telescopes: Mechanics

The focal ratio of f/3.2 comes with many challenges concering the telescope mechanics. The Horizon series' construction is a completely new design,

developed from the ground up to meet the technical demands of the optical system.

A key aspect when developing the mechanics for this series was to ensure, that a dobsonian with such a large aperture and additionally short focal length

could be handled just as easily and intuitively as a similar instrument with a more common, longer focal length.

Countless hours of design development and prototype building have been invested. And now after more than two years of extensive field testing of the

final design, it could be proven that this goal was achieved.

After you have arrived at your usual spot for observing, your telescope is set up in less than 10 minutes thanks to its efficient design. Since the secondary

mirror can be left installed inside the secondary cage for most transport purposes, you only have to adjust the primary mirror. You do so using Polaris as

soon as the primary has completely cooled down after 20 minutes. Due to the special truss design as usual only a quarter to a half revolution of the two

large star knob nuts is necessary to reach perfect alignment. You remember some rare nights when you even didn´t need to adjust the telescope at all,

since it had still been perfectly aligned from your last expedition. You know, this is remarkable for a telescope with an f/3 focal ratio. Once the telescope

is aligned, it stays so for the rest of the night. You attach and prepare your ParaCorr coma corrector, check on your eyepieces and star charts and so only

shortly after arriving you are ready to set out on your walk trough space, heading for the first of many objects your going to visit tonight.

The Horizon series is a balanced concept between being a lightweight construction and the guarantee of stability and rigidness. Critical components have

been designed a bit more massive and sturdy (for example the lower truss holders or the cross brace between the side bearings) and additional braces are

part of the concept, also technically advanced materials and manufacturing techniques are used to achieve optimal balance (like the very light but also

stable carbon fiber trusses and the welded aluminum frames).

This balanced approach leads to an effective yet light design. With the 20“ f/3 weighing 40kg and the 25“ f/3 weighing 63kg one person can still easily

setup and dissassemble a Horizon all on their own.

The following pages go more into detail concerning key components of the telescopes.

1) Secondary Cage

The secondary cage of the Horizon series is based on two matt-black powder-coated aluminum frames in octagonal form. These frames are connected via

six short carbon fiber trusses as well as one machined, quality carbon fiber plate. To ensure maximum torsion stability for the spider, additionaly coated

aluminum profiles are attached to the upper frame.

The spider itself is up to 60mm broad and braced eccentrically within the upper of the two octagonal frames. The massive secondary holder is then attached

to the middle component of the spider via two star knob nuts. That way the secondary mirror does not need to be readjusted even after removing it from the

cage before. To avoid fogging of the secondary during humid nights a specially dimensioned heating system is installed in every Horizon telescope.

The focuser used is the proven 2“ Moonlite with an 1:8 reduction ratio that allows for an especially smooth and exact focussing process. Additionally almost

every viewing finder can be used and optionally a Spheretec filter slider with space for three filters can be installed.

The secondary baffle has been optimizied for use during a bit windier conditions and consists of matt-black PE. It is firmly attached to the octagonal frames

of the secondary cage via star knob nuts.

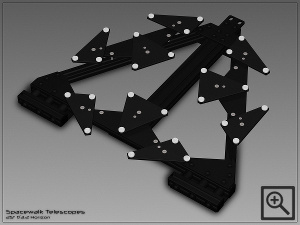

2) Trusses and struts

To achieve maximum torsion resistance within the design, the lower truss holders are milled out of solid material. They firmly support the eight carbon

trusses and hold them exactly in position at any angle. With a diameter of 20mm (20“) or 24mm(25mm) the trusses themselves are very rigid but still also

very lightweight.

When setting up the telescope, the four truss pairs are slid over the matching truss holders and fastened into position via large M8 star knob nuts that can

be easily gripped even under very cold conditions. On the upper end the trusses are clamped to the lower octagonal frame of the secondary cage via a system

consisting of four guiding notches and sturdy lever screws.

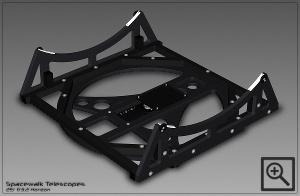

3) Mirror Box and Mirror Cell

Supporting a mirror with a focal ratio of f/3 is an ambitious task requiring an expert concept concerning the mirror cell and -box. No torsion or repositioning

whatsoever must occur to ensure top performance.

This is why the Horizon mirror cell has been multiply reinforced and was additionally integrated into a welded aluminum frame. The primary mirror floats on

18 (20“ model) or 27 (25“ model) support points. Laterally the mirror is supported by several ball bearings that are aligned to the line representing the mirror´s

center of gravity.

The adjustment of the mirror box can comfortably be conducted from above. The cell itself is very compact, even in the 25“ version the height of the frame

including the coverplate and the four supporting feet is only 14cm.

In case the primary mirror needs to be cleaned after a while of extensive usage or if it is to be put separately in the optionally available transport box, the cover

plate can quickly be removed completely without any tools. The mirror then is easily accessible.

4) Rocker Box

The basis of the rocker box also is created by welded aluminum profiles with a durable, matt-black powder-coating. The corners on the inside are further reinforced

with four additional profiles.

The tread made of solid birch mutiplex wood is attached to the bottom of the rockerbox basis. Just like the side bearings the sliding mechanism between the two

components is realized via the proven material combination of teflon and ebony, resulting in very low initial resistance and friction when moving the telescope,

therefore ensuring exceptionally smooth and exact guidance.

In the middle of the rockerbox an aluminum plate is installed which prepares the telescope for the optional upgrade with digital setting circles (BDSC). If this upgrade

is chosen, the azimuth encoder and the control circuit containing the bluetooth module of the BDSC are attached to the aluminum plate. The setting circles then can

easily be paired to smartphones or tablets via a wireless bluetooth connection. The rockerbox additionally offers enough free space for the power supply consisting

of a battery holder for 6 mignon batteries/rechargeable batteries.